Do-it-yourself trunk for a tilt UAZ 469. DIY expedition trunk - more space in the cabin. Expedition trunk for UAZ loaf

Yes, you will be glad. You're happy until you see the price tag. Another thing is a do-it-yourself expeditionary trunk. However, you need to think about several issues regarding the shape and weight of the cargo you are going to transport.

Materials and market trends

We present to you the main contender for applause - aluminum. Aluminum sheets are lightweight and difficult to bend or puncture.

More often than not, owners of domestic cars want to do this kind of work with their own hands. Let's take, for example, a roof rack for a Niva or UAZ. A suitable material for the structure would be a thin-walled profile pipe. In other cases, ferrous metal or stainless steel, as well as many others, are possible.

Step-by-step manufacturing instructions

As an example, let’s take a trunk being manufactured from a metal profile.

We measure the length and width of the roof. We need to find out the weight of the future structure, taking into account the material and measured parameters. How to do it? Microsoft Excel is here to help you. The weight of the structure will be shown immediately after recording all the characteristics.

We will weld the perimeter of the future trunk, and at an equal distance inside the perimeter we will weld two jumpers that will “hold” the structure. Railings will be installed to these jumpers, and the platform will be connected to the railings. After the main intermediate jumpers, for greater strength. This brings the assembly of the supporting frame to an end.

Next, the profile pipe comes into play. It will serve as a connecting element between all jumpers. For aesthetics and aerodynamics of the trunk, an arch is installed in the front part of the structure. In the places where it bends there should be a sector, and at the edge there should be an overlap of 5 cm. We weld the arc to the front part of the surface, and also add jumpers.

What is an expeditionary trunk without sides? It is advisable to make removable sides in order to change them as needed. The sides will be attached to holes that need to be welded and plugged with bushings. This will prevent the profile from deforming when tightening the bolts.

Now about how to make the sides themselves. We will need 8 racks, each about 6.5 cm long. The fastening pin can only be welded between two holes, which is what we will do. After drilling two holes, we will weld the stud.

Side top bar

Have you forgotten how we bent the front arch? We also bend the side upper crossbar. One, another. Next, we weld the bushing to the bend point of the crossbar on the side so that the upper part of the front crossbar is securely fastened.

Now all the work is almost done. The hour has come for creative motorists. We need to paint the entire structure and give it a little style. To avoid rust, we recommend applying a coat of primer and only then thinking about paint. Among soil solutions, the most resistant to salt influences is soil containing zinc.

After applying a layer of primer, you should wait at least a day, and then use regular enamel and apply the desired color. Many people don’t like the way the bolts look at the joints of the structure. To avoid an unsightly appearance, you can place decorative nuts in these places. Here's a modern trunk for you.

What else could I add?

The main function of a roof rack is to save space inside. By installing additional equipment, you can expand its functionality.

- “ ” - lanterns that will illuminate the road even better.

- There is space for a hijack and a shovel in the inner and outer sides. Oh, how the gardeners will be happy.

- If you often drive through overgrown areas, such as forests, you can install branch guards. They will protect the glass from damage.

Don’t forget also that the expedition vehicle protects the roof itself well from dents. As you can see, such a trunk can serve as a good tool not only for saving space, but also for installing useful equipment. In addition, in addition to the racks themselves, other structures can be attached to the roof rails for transporting fishing or hunting equipment.

As you can see, it’s possible to make a trunk with your own hands. Larger Mitsubishi L200s will require a side ladder. For small foreign cars, a reinforced frame will be sufficient.

The trunk installed on the roof of the UAZ Bukhanka will allow you to place most of your things, ensuring the comfort of passengers.

If the trunk is used irregularly or you don’t want to spend money on buying it, you can make it yourself from scrap materials that every car enthusiast probably has in his garage.

Do-it-yourself trunk for UAZ loaf, drawings

Thanks to its spaciousness and high cross-country ability, the Bukhanka is considered an excellent expedition vehicle. However, during long trips, expeditions or travel, a comfortable stay for passengers in the cabin is only possible when there is a minimum of things in it.

An expeditionary trunk can not only transport a large amount of cargo, but also accommodate oversized cargo that exceeds the dimensions of the cabin. It should be noted that the trunk on the Bukhanka also has a protective function.

The trunk protects the roof of the car from impacts from branches.

The trunk is installed on mounts that are placed so that the pressure from the load on the body becomes minimal. Therefore, even when fully loaded, the weight of the load does not deform the roof. You can also install additional equipment on the expedition rack: a spotlight to illuminate the road, an antenna, etc.

To make a trunk for a loaf with your own hands, you will need drawings, which you can see below.

Dimensions

When starting to make the roof rack, you need to measure the roof and mark where the supports will be placed. Only after this can you think through the design of the future accessory, draw a drawing, and calculate the weight of the trunk.

That is, by the time the work begins, the master should have in his hands:

- measurements taken;

- calculated frame weight;

- total weight of all trunk parts.

The overall weight of the rack is important for design. It depends on the material used.

- Aluminum- an excellent material for making structures: it is durable, lightweight, durable, flexible, etc.

- Another option is to use profile thin-walled pipes, which also weigh a little.

- Another simple option is stainless steel or plain metal strips. These materials are heavy, but easy to process.

The standard dimensions of the trunk for a loaf can be taken as follows:

- total length of the structure - 3650 mm;

- rear width - one and a half meters;

- front width - 1400 mm;

- a longitudinal rib runs through the center of the structure;

- transverse stiffeners can be installed with an equal distance between them of 566 mm.

Some people make a trunk with dimensions corresponding to the roof, for others it is more convenient to make a smaller structure: for example, 2160 mm long, 1200 wide both front and rear.

The distance between the stiffeners in this case is calculated differently. In order for the load to be evenly distributed over the roof, you need to make at least 8 supports.

Expedition trunk for UAZ loaf

First, the lower trunk frame with stiffeners is welded, then the upper retaining perimeter. To improve the aerodynamics of the structure at the front, either the structure is narrowed or the corners of the frame are rounded.

Yes, you will be glad. You're happy until you see the price tag. Another thing is a do-it-yourself expeditionary trunk. However, you need to think about several issues regarding the shape and weight of the cargo you are going to transport.

Materials and market trends

We present to you the main contender for applause - aluminum. Aluminum sheets are lightweight and difficult to bend or puncture.

More often than not, owners of domestic cars want to do this kind of work with their own hands. Let's take, for example, a roof rack for a Niva or UAZ. A suitable material for the structure would be a thin-walled profile pipe. In other cases, ferrous metal or stainless steel, as well as many others, are possible.

Step-by-step manufacturing instructions

As an example, let’s take a trunk being manufactured from a metal profile.

We measure the length and width of the roof. We need to find out the weight of the future structure, taking into account the material and measured parameters. How to do it? Microsoft Excel is here to help you. The weight of the structure will be shown immediately after recording all the characteristics.

![]()

We will weld the perimeter of the future trunk, and at an equal distance inside the perimeter we will weld two jumpers that will “hold” the structure. Railings will be installed to these jumpers, and the platform will be connected to the railings. After the main intermediate jumpers, for greater strength. This brings the assembly of the supporting frame to an end.

Next, the profile pipe comes into play. It will serve as a connecting element between all jumpers. For aesthetics and aerodynamics of the trunk, an arch is installed in the front part of the structure. In the places where it bends there should be a sector, and at the edge there should be an overlap of 5 cm. We weld the arc to the front part of the surface, and also add jumpers.

What is an expeditionary trunk without sides? It is advisable to make removable sides in order to change them as needed. The sides will be attached to holes that need to be welded and plugged with bushings. This will prevent the profile from deforming when tightening the bolts.

Now about how to make the sides themselves. We will need 8 racks, each about 6.5 cm long. The fastening pin can only be welded between two holes, which is what we will do. After drilling two holes, we will weld the stud.

Side top bar

Have you forgotten how we bent the front arch? We also bend the side upper crossbar. One, another. Next, we weld the bushing to the bend point of the crossbar on the side so that the upper part of the front crossbar is securely fastened.

Now all the work is almost done. The hour has come for creative motorists. We need to paint the entire structure and give it a little style. To avoid rust, we recommend applying a coat of primer and only then thinking about paint. Among soil solutions, the most resistant to salt influences is soil containing zinc.

After applying a layer of primer, you should wait at least a day, and then use regular enamel and apply the desired color. Many people don’t like the way the bolts look at the joints of the structure. To avoid an unsightly appearance, you can place decorative nuts in these places. Here's a modern trunk for you.

What else could I add?

The main function of a roof rack is to save space inside. By installing additional equipment, you can expand its functionality.

- “ ” - lanterns that will illuminate the road even better.

- There is space for a hijack and a shovel in the inner and outer sides. Oh, how the gardeners will be happy.

- If you often drive through overgrown areas, such as forests, you can install branch guards. They will protect the glass from damage.

Don’t forget also that the expedition vehicle protects the roof itself well from dents. As you can see, such a trunk can serve as a good way not only to save space, but also to install useful equipment. In addition, in addition to the racks themselves, other structures can be attached to the roof rails for transporting fishing or hunting equipment.

As you can see, it’s possible to make a trunk with your own hands. Larger Mitsubishi L200s will require a side ladder. For small foreign cars, a reinforced frame will be sufficient.

The SUV from the Ulyanovsk plant is equipped with longitudinal arches or roof rails. But not every UAZ Patriot model is equipped with such a device. More details about roof rails on the UAZ Patriot can be found here (link to website). Today we will pay attention to the roof rack of the UAZ Patriot SUV. There are four types of trunk for an SUV:

- sports;

- tourist or expedition;

- country house or household;

- autobox.

Today we will pay attention to the expeditionary trunk for an SUV. What is it, how is it installed and is it possible to do it yourself at home? These are the questions we will consider in this material.

The expedition trunk is intended, first of all, to be able to transport cargo primarily of an expeditionary nature. Such cargo includes various tools, devices, tents, etc. The expedition version must have a structure in the form of a lattice bottom with sides. Why is this necessary? The lattice bottom will allow you to transport things or objects on it without additional securing them. The sides are also designed to prevent the cargo from falling out of the trunk, so these conditions are mandatory for this version of the product.

Today, car markets are crowded with various options for expedition vehicles for the UAZ Patriot SUV. You can find domestic types, and foreign, and home-made, and factory-made. But which ones to choose? The choice of product should be based on the following criteria:

- the material from which the product is made;

- product shape;

- build quality. If the welds are clearly visible or the steel from which the trunk is assembled is too thin, then it is better not to buy such a unit, as you will suffer more;

- installation method. Based on the installation method, the following options for luggage racks are distinguished:

- Mounting on roof rails. The simplest and most common installation method. It is enough to install and secure the product. There is no need to perform any additional work: drilling, cutting, etc.

- Installation on gutters. This fastening option is also one of the simplest, but less reliable than the next one.

- Installation in roof mounts. To do this, holes are made in the roof of the car and a trunk is installed. This mounting option is the most reliable, but requires drilling the roof, which negatively affects the structure of the car.

So, fastening to the roof rails is carried out using special brackets. This option is acceptable for those who do not want to spoil the structure of the car and try to avoid drilling the body part. The disadvantage of this type of fastening is the design - the trunk, which is attached to the roof rails, does not look very nice.

Installation on roof rails

Installation of the product on gutters

The UAZ Patriot SUV, however, like many domestically produced cars, is equipped with special grooves on the roof, called gutters. Foreign-made cars have long moved away from such a device, but the essence of these gutters is that it is in this groove that an expeditionary trunk can be completely freely secured.

Fixation is carried out using special L-shaped brackets. This mounting option also does not require disruption of the roof structure, which is why it is also popular. But there is also a downside to this fastening option, which is the unreliability of fastening. That is, the possibility cannot be ruled out that the trunk will not rip out under the influence of a large load. Therefore, it is very important not to overload it.

DIY expedition rack for gutters

If you can’t find a trunk that attaches to gutters or the options for such products are not at all what you imagine, then you shouldn’t despair. You can solve the problem by making the unit yourself. Of course, you will need the help of a welder, but first you should sketch out a rough diagram on a piece of paper. The resulting drawing should be handed over to the welder along with the material. So, let’s not dwell on the type of product itself, but consider what the brackets for an expeditionary roof rack for gutters are.

To begin with, select the thickness of the steel brackets. It is desirable that it be at least 2mm and no more than 4mm. You only need three different elements:

- Base plate;

- Pressure bar;

- L-shaped bracket.

The photo below shows an example of these parts.

Once such parts are ready, you will need to connect them to the main structure of the trunk and install them in the gutters. The result will be this version of an expeditionary trunk for the UAZ Patriot, which is fixed into the gutters.

Everything is very simple, but the only thing that is important to consider when installing it yourself is the installation of rubber spacers between the trunk brackets and the roof. This is necessary in order not to damage the car body.

The most popular version of the “expedition vehicle” is the RIF expedition trunk for the UAZ Patriot, which also has a method of installation using gutters. The quality of RIF is quite high, it even withstands the maximum permissible masses, but as practice shows, gutters fail. The dimensions of the RIF are 1200x1900mm, which perfectly places the product on the roof. Additionally, lighting can be installed on the trunk.

Roof mount

Attaching the rack to the roof of the car is the most reliable option, since there is practically no chance that the product can get lost while driving. The only drawback is the need to drill holes in the roof. If you had standard roof rails, then many luggage racks are designed specifically for these mounts. But if the standard crossbars are not installed from the factory, then the fixing option is solved by making holes with your own hands. This process is simple, but requires removing the roof trim from inside the cabin.

After removing the roof sheathing, holes in the roof of the required diameter are marked and drilled. Holes are drilled from the inside (in the internal frame) using a cutter. This is necessary in order to secure the product with nuts. Before installing the product on the roof, be sure to install rubber spacers at the fastening points so as not to damage the paint and prevent corrosion of the roof.

Disadvantages of expedition racks

So, we looked at the main purpose of this unit for the UAZ Patriot SUV, how it is installed and what mounting options are available. In addition to all the advantages, “expedition vehicles” also have some disadvantages, so driving with it on the roof without use is simply irrational. The disadvantages include:

- Reduced aerodynamic characteristics. The trunk, with its massive structure, is simply an obstacle to the oncoming wind, so it slows down the car and reduces its aerodynamic properties.

- Deterioration of aerodynamics leads to increased fuel consumption. The larger the volume of cargo transported, the greater the fuel consumption.

- If the fastening is done poorly, this leads to deterioration of sound insulation.

- Poor vehicle handling due to improper weight distribution.

Therefore, based on all of the above, it should be concluded that it is best to install the trunk when necessary. Therefore, its fastenings must be mobile, that is, easily and quickly removed. The best mounting options are:

- through roof rails;

- into drainage grooves.

Thus, by making the right decision, you will protect yourself from unnecessary and unnecessary additional costs for gasoline and spare parts.

How often does your Patriot break down?

A car roof rack has a huge number of advantages. The main tasks it performs:

- Creates places for transporting additional things and accessories.

- Provides a base for installing additional lighting fixtures and also protects the roof from damage.

Speaking about the advantages, it is impossible to note the disadvantages of this design:

- The aerodynamics of the car deteriorate significantly, which leads to fuel consumption.

- In some cases, when serious mistakes are made, noise insulation and controllability deteriorate.

Roof rack

Roof rack

What is the trunk made of?

To make a luggage base with your own hands, you will need material for its manufacture. The best solution would be metal, the weight of which is insignificant but durable. For the design, the best option would be:

- Aluminum.

- Stainless steel.

- Profile tube.

Many car owners believe that aluminum is a suitable material for making their own trunk frame. It is lightweight, weather-resistant and rust-proof. Using aluminum you can make the most daring designs.

Strong and flexible steel sheets - what else is needed to implement a high-quality design? The disadvantage is the weight, which significantly exceeds the weight of aluminum and the profile tube.

Profile pipe

Profile pipe

A profile tube with thin walls is often used as a material for a “domestic type” trunk.

After choosing the right material for the structure, we move on to the stage of measurements and calculations with our own hands. Here the weight, dimensions, necessary elements for the future design and approximate cost are determined.

Taking measurements for the roof rack

First, measure the width and length of the car roof. Then we can use serial ones or make our own drawing, which takes into account:

- The basis of the design.

- Frame.

- Amplifiers for the structure (jumpers).

- Boards.

Trunk diagram

Trunk diagram

Manufacturing stages:

Attention: to avoid damaging the body paint during installation and operation of the structure on the roof, we glue special rubber bands under the mounting posts.

If desired, you can make additional parts for the Hunter that you will need during operation. For example, a streamlined front body that will provide better resistance when driving at high speeds.

Required tools:

- Drill.

- Bulgarian.

- Measuring equipment.

- Scissors.

- Welding equipment.

- Rubber.

- Cardboard.

- Adhesive composition.

- Dye.

Trunk for UAZ Hunter

Trunk for UAZ Hunter

Second manufacturing method:

- We take measurements on the Hunter roof with our own hands, using a grinder to make blanks for lintels from angle steel.

- We create a template of cardboard stands for installing the structure. First, we place the cut out template on a metal sheet, then we cut it along the edging.

- We install the cross member using welding. We take measurements on the roof to determine the stability of the trunk.

- Using cardboard, we create a new template that will reflect the shape of the side mounting holes of the trunk.

- We attach the structure to the roof for measurements. We mark the holes for the end fastenings of the trunk to the Hunter support struts. We take a drill and drill the previously marked places on the structure and use the drawing for verification. Install the mounting bolts.

- We use sandpaper to clean seams and other metal parts. Clean and allow time to dry after degreasing. To paint the structure, you can use either simple metal paint or a spray can, which will speed up the painting process itself, as well as the drying time.

Hello everybody! My name is Gastinov Albert, I represent the online store “Podgotoffka.ru”.

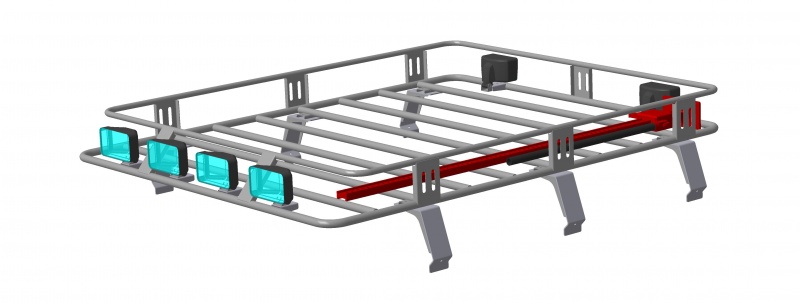

Today I will try to tell you in detail about the expeditionary luggage racks of our production and additional accessories that increase its functionality.

“An expedition trunk is that simple device that sometimes carries the most valuable cargo on expeditions, tourist outings, or just family weekend trips into nature. Depending on the type of activity and your preferences, our company designs and produces a wide range of different variations of the appearance of luggage racks. Here you can find for yourself: compact luggage racks, for transporting small bags and small items; budget (amateur) luggage racks, which practically have no own weight and can be installed even on sedan-type cars; large racks installed over the entire roof area of your car.

In addition to the expeditionary focus of our luggage racks, there are also models that may be suitable for enterprises in the oil and gas industry, hydraulic industry, construction organizations that simply need to transport long items (pipes, boards, rolled metal, etc.) or for hunting or fishing trips so that you can transport the necessary equipment and prey.

In addition to the models we already produce, our company can produce trunks of any size and almost any shape according to your requirements.

Your fantasies and our capabilities are interesting options for development and additions to our products!”

The main task that falls on us as a manufacturer is not only high quality and beautiful, but also reliable. Reliability lies in the fastenings that allow you to secure the luggage rack basket to the roof of the car. We currently have three types of fasteners in our assortment:

Based on the dimensions, types and shape of the car roof, a trunk basket is selected. More often than not, our clients already buy ready-made solutions, i.e. fasteners and basket together from the presented model range on our website.

The trunk basket is made of steel pipe with a diameter of 20 mm, a profile of 20x20mm and 20x40 mm, and a mesh with a cell of 20x20 mm. The entire structure of the basket is entirely welded, so the trunk frame is stronger and more reliable, unlike prefabricated products.

In the trunk basket, based on the model and make of the car, holes are drilled for bolts, grooves are milled in the fastenings to allow the fastenings to be adjusted in width. For mounting on roof rails, it is possible to adjust the length. This greatly simplifies the process of installing and choosing the location of the roof rack.

All products are sandblasted before painting (to prevent corrosion after painting). Then they go to the painting booth, where they are coated with powder paint. The main color of the coating of all products is black, because... goes well with almost any body color. If desired, of course, painting in other colors is possible, but these points are agreed upon individually with each buyer.

Our product range is not limited to roof racks and roof racks. All luggage racks can be additionally equipped with:

- Mounting for rack jack

- Spare wheel mount

- Attachment for ax and shovel

- QUICK FIST fastenings and their analogues

- Branch guards

- Net for securing cargo

- Tightening strap

- Additional optics

- Wiring kit for connecting additional optics

The list is not complete because The possibilities for implementing functionality are very, very large.

Let's look at them in more detail:

1. The mounting kit for the rack jack consists of two brackets that are installed on the trunk racks, as well as pressure plates and “wings” for securing the rack jack.

2. Spare wheel mount. Installed on pre-assigned places on the trunk. An insert with bolts is screwed into the trapezium of the bracket to secure the spare wheel. This insert allows you to adjust the height, which allows you to mount wheels of different sizes.

3. Attachment for an ax and a shovel. Can be installed anywhere and in any width, depending on the length of your tools.

4. When manufacturing a trunk, we always take into account all possible wishes of customers, so we can prepare in advance places on the trunk racks for universal QUICK FIST mounts and their analogues.

5. Branch cutters or branch cutters. This is a separate item of goods. Which can be purchased in our online store. There are a lot of advantages from such an inexpensive addition. Protection of the body and windshield from large tree branches and a more brutal appearance of the car.

6. Branded awning. Simply a must-have for all travelers and lovers of long trips. The awning is made taking into account all dimensions of the trunk, its shape and additionally installed fasteners. The awning will allow you to store all the things packed in the trunk, protect the bottom and frame of the basket from precipitation, snow, leaves and rain.

7. Using an elastic mesh or tie-down straps, you can secure high and bulky loads. This allows them to be immobilized and eliminate the possibility of moving around the trunk.

8. A waterproof luggage bag will provide convenient transportation of all your essentials, including food, clothing and bedding. Having very large dimensions, you have the opportunity to maximize the load on the trunk space in the car. The bag is made of waterproof material, which allows you to protect all your belongings from rain and snow.

9. All luggage racks of our production are equipped with places and brackets for installing additional light. Headlights and LED beams can also be selected on our website.

10. The wiring kit will allow you to easily install optics without going to different stores, with connections in different combinations. The kit is designed to connect 5 headlights, including LED beams.

When choosing this or that trunk, compare all your needs, choose the design you like, and the reliability of the design will be our responsibility, for which we are fully responsible!

Photos for the article were prepared by:

Pavel Maltsev “Podgotoffka.ru”

Anton Emelyanov “inPhoto.pro”

What is the most important thing when traveling? That's right, the things you need while traveling should be at hand. But the question arises - where to load them? On regular cars there is a trunk for this purpose. What about the UAZ Hunter? It would seem that everything is in order here. Behind the rear seats there is a fairly large compartment where you can load anything you want. But... Most often it is used to create additional space. After all, a company usually goes on a camping trip in a UAZ Hunter, and the extra space in the cabin is used 100%. Where can I download the necessary “little things”? In other cars, the roof rack is used for this purpose. Is it worth it, and is it possible to do something in this regard on the UAZ Hunter? We need to figure it out.

Why is there a roof rack?

This is the simplest question. The car interior is usually full of people. Many people arrange a kind of “office” from the “aft” part with a folding table, a mini-bar and so on. A The UAZ Hunter, whatever one may say, is a car for hunting, fishing and long-distance travel. And here you need to provide for a lot, but you don’t really want to sit in the cabin resting your feet on a rolled-up tent, a fishing pot, buckets, and other things necessary for a real traveler. Towing a trailer? Well, some people do that too. But most resort to the old, proven roof rack.

Disadvantages of such a device

- Aerodynamics.

- Sustainability.

- Risk of loss.

Violation of aerodynamics, and as a result, increased consumption. This is the main argument. But honestly, we can say that aerodynamics is by no means the main quality of the UAZ Hunter. And a properly installed roof rack will not make it much worse.

Sustainability. Well, of course, if load 700–800 kilograms of equipment onto the roof, then there is no doubt. But if you approach this issue wisely and distribute the weight correctly, then its design stability will not even notice 2-3 centners on the roof. This also includes the risk of “loss”. Everything is in the hands of the owner.

Types of roof racks

Conventionally, they can be divided into three groups:

- Closed (streamlined).

- Open longitudinal.

- Transverse.

Typically, closed trunks are factory-made products made in the form of streamlined boxes, reminiscent of a boat.

Important! These are often used for foreign-made SUVs. They are beautiful and ergonomic, but most are very small in capacity.

Open trunks are the most popular. They are easy to manufacture and allow you not only to take more cargo, but also to position it more conveniently.

Longitudinal racks

This is a rather original option. There are always two arches located on the roof in the direction of travel of the car. If necessary, transverse beams are attached to them and a load is placed. It is secured with a special spring cable or strong cord.

Attention! The crossbars are secured using clamps built into them.

The longitudinal beams have a square cross-section and are firmly bolted to the roof of the UAZ Hunter.

Cross roof racks

This is, in principle, a well-known option for everyone. Removable versions are mounted in the same way on other types of cars that are not SUVs. The convenience of these units is that they are completely dismantled when they are not needed. In addition, they are usually much lighter than other options due to their design.

Of the minuses, first of all, it is necessary to note the great fragility of these roof racks. They are made from 2 materials:

- aluminum,

- thin steel rods.

The cross section ranges from 7 to 12 millimeters. They try to make these roof racks for the UAZ Hunter with their own hands, because it’s quite simple.

The shape of this part resembles a flat box made of walls consisting of thin elements.

Make your own trunk

So, the owner decided to show himself as a real traveler and make a place for transporting goods himself. Great. Where should I start?

Select the type of part based on the features listed above. Select materials and tools. And forward.

.jpg)

Tools

The set of materials is already known. Now regarding the tools. Here you will need to prepare:

- electric circular saw for metal;

- electric welding;

- sandpaper;

- hammer.

This is quite enough to make the device.

Attention! If you still decide to make a trunk with longitudinal fastening, you will need a drill.

Manufacturing process

Now the main thing is the correct calculation. Accurately measure the distance between the protrusions on the roof to which you can attach the rack. After this, cut from a rod with a thickness of at least 10 mm. Two main arcs and weld fastening clamps to them. There is no need to be tricky with them. It's better to buy ready-made ones. After this, cut the pieces that will make up the “bottom” of this basket. Weld them at equal distances. Along the perimeter of the resulting “rectangle”, scald with a single rod and close. Now weld the same square (exactly this size) and weld it on thin connecting pieces. The length of these pieces will be the height of the side of the trunk of the UAZ Hunter.

All that remains is to carefully sand it with sandpaper (after complete cooling from welding) and paint it. For special connoisseurs, as an option, you can chrome plate the surface of the product. You can install it on the roof and try loading it.

Making a longitudinal trunk

Here, on the one hand, everything is even simpler. The tools are the same, only a square metal profile is used as the material, and two “arcs” are bent from it to be attached to the roof of the UAZ Hunter. Holes are drilled in the roof to secure the neatly flattened ends of these “arcs” having similar holes. After this, after “designer” processing, that is, painting, the arcs are tightly fixed in place.

After this, a frame is prepared that will be attached to these arches. This is a matter of the car owner’s imagination. In principle, there are no special restrictions here. The simplest and most popular option is a set of aluminum slats with fastening devices. When assembling, they can be placed with different distances between each other. Their convenience is that they are conveniently and compactly stored. You can do it right in the UAZ Hunter showroom. Well, as an option , you can make a removable basket based on the principle of a transverse trunk. The main thing is that the anchor points coincide.

By the way! Two transverse arcs can be positioned in a similar way, as shown with the factory-made option in the video.

Bottom line

In principle, there is nothing particularly difficult about making this device with your own hands. Well, whoever doesn’t want to spend extra hours fiddling with metal, welding and tools can easily purchase this “device” at any specialized automotive store. Or buy it in online stores. And install it yourself. Well, when the issue of additional cargo space on the UAZ Hunter is resolved, you can safely set off on an exciting journey, with confidence in your reserves.

And as usual, a useful video on this topic:

It is not uncommon for a completely new trunk purchased at a VAZ branded car dealership to fall apart after the first trip out of town on vacation. The trunk was presented in a collapsible version, with pipes of predominantly square and round sections.

The thickness of the side steel posts was 1 mm. The side longitudinal fastening M10 passes through steel transverse beams, which significantly damages the reliability of the entire structure. Another drawback was the width of the transverse tubes at the point of their attachment directly to the roof of the UAZ itself, which exceeded the required figure by as much as 20 mm.

During the analysis of the engineering structure, it became clearly clear that the structure needed basic redevelopment. The photo above shows a new design, which was made using all the components of the old design.

Stages and procedure for rearranging the trunk.

1. First you need all the threaded bushings. which are soldered, both square and rectangular - cut off.

2. Next, you need to perform an assembly, the so-called “interception,” using 1,2,3 U-shaped cross beams that remained from the old trunk, while it is very important to maintain the distance between the supports at 1520 mm. Afterwards, you should weld the seams, having previously shaded them to size.

3. While controlling the diagonals, you need to connect the longitudinal transverse beams to each other, welding their connections.

4. Now it is necessary to weld the side and rear sides, which correspond to the following parts in the diagram: 4,5,6,7,8,9,10).

5. Then, you need to join the original pipes in pairs; parts 12 (intermediate cross member) and 11 (longitudinal insert) must be cut to size.

7. When all the seams are finally welded, finishing touching and cleaning should be done.

8. All that remains is to paint and evenly prime the trunk itself.

Using the drawing below, and having the necessary material, you can make a HUNTERa trunk from scratch.